top of page

Changzhou Hongfa Zongheng Advanced Material Technology Co., Ltd (PG Tex)

Changzhou, China

R&D Engineer, Project Lead

May 2016 - Oct 2018

Modular Lightweight Electric Bus.

Project on Fiber Reinforced Plastic (FRP) Composites/Aluminum Hybrid Structure

-

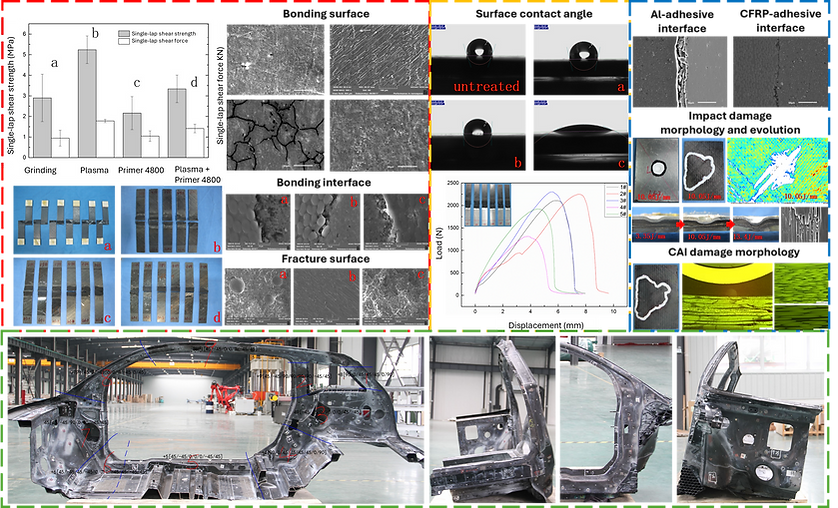

Investigated different surface treatment methods (atmospheric pressure plasma, solvent-based adhesion promoters, and mechanical grinding) to enhance bonding strength between FRP composites and aluminum substrates.

-

Examined surface fiber lay-up on bonding strength and evaluated the performance of elastic and structural adhesives in hybrid structures through single lap shear, T-peel, drop-weight impact, and compression after impact (CAI) tests.

-

Conducted fracture analysis using ultrasonic A-scan, metallographic microscopy, and scanning electron microscopy (SEM) to characterize failure mechanisms.

-

Developed a semi-empirical model to correlate impact energy, CAI strength, and damage, providing a foundation for hybrid CFRP/Al structure design.

Fully Assembled Composite Bus.

Project on Modular Lightweight Electric Bus with Composite Bus Body

-

Led the team to optimize the bus body structure and completed the final assembly.

-

Implemented HP-RTM, VARI, and Hot Press manufacturing processes, developed three assembly fixtures for side and roof skin panels, and refined the connection method (grooving one side of the FRP laminate, inserting the bolt, then bonding it with the outer panel), significantly reducing product rejection rate and improving manufacturing efficiency.

-

Successfully passed the state road performance test, achieving 30% weight reduction, 40% reduction in assembly investment costs, and 110% increase in internal space compared to traditional integrated steel buses.

-

Authored “Manufacturing Process Instruction and Improvement Schemes for Modular Lightweight Composite Bus”, officially adopted by the company as a reference for volume production.

Beihang University

Beijing, China

Graduate Research Assistant

Sep 2013 - Mar 2016

Composite Bus Body Design.

Research on the Application of Modular Lightweight Composite Bus Body

-

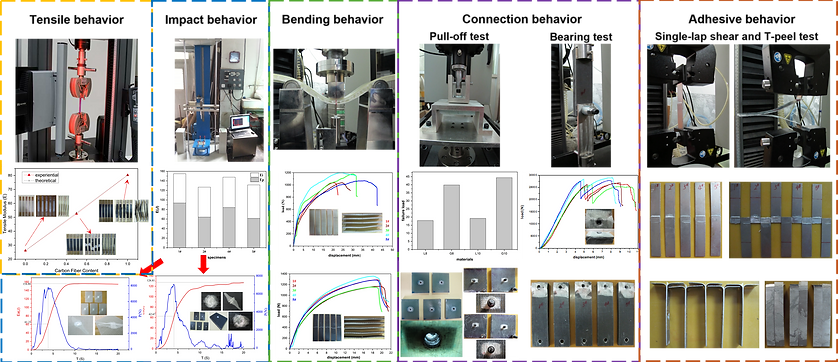

Designed a modular bus body using a honeycomb sandwich structure composed of thermoset FRP outer panels, thermoplastic FRP inner panels, and a PP honeycomb core; employed VARI, RTM, and Hot Press manufacturing processes.

-

Defined the connection interface between the composite bus body and U-shaped steel frame, including fiber type, stacking sequence, and connection method (bolt fastening with metal-embedded composites as nuts), validated through mechanical testing (tensile, drop weight impact, three-point flexural, etc.).

-

Developed a standardized pull-off test for metal-embedded composites and designed custom testing devices.

-

Authored one national invention patent, "Manufacturing Methods of Composite Bus Laminates," and one utility model patent, "Embedded Connector of Composite Bus Laminates," on behalf of the industrial partner.

Characterization of Radius Fillers.

Research on Automatic Pulling Equipment of Radius Fillers

-

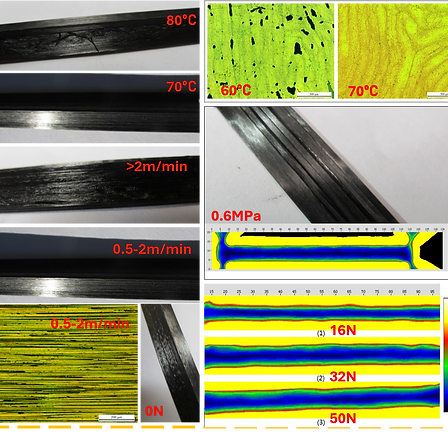

Optimized key equipment parameters (temperature, pressure, pulling speed, etc.) through mechanical testing of prepreg radius fillers and metallographic observation.

-

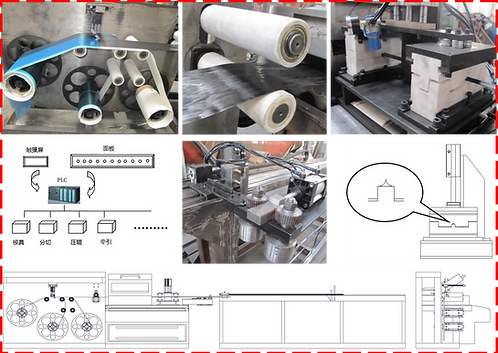

Developed fully automatic pulling equipment by integrating measuring instruments, controllers, actuators, operating panels, and other automatic tools, enabling the production of 5 m-long, high-quality radius fillers, now applied in high-speed trains, wind turbine blades, and aerospace applications.

-

Achieved a production rate of 2 m/min, significantly improving manufacturing efficiency.

Reference paper: E. L. Shi, Y. X. Duan, D. X. Yan, and S. C. Xu, “Study on Automatic Pulling Equipment of Radius Fillers” Applied Mechanics and Materials, vol. 799–800, pp. 452–457, 2015, doi: 10.4028/www.scientific.net/AMM.799-800.452.

Manufactured Composite Helmet.

Research Hybrid Fiber Reinforced Helmet with High Resistance to Impact

-

Simulated the resin flow process and pressure distribution using an in-house code, optimized the flow medium design, and determined the efficient flow channel.

-

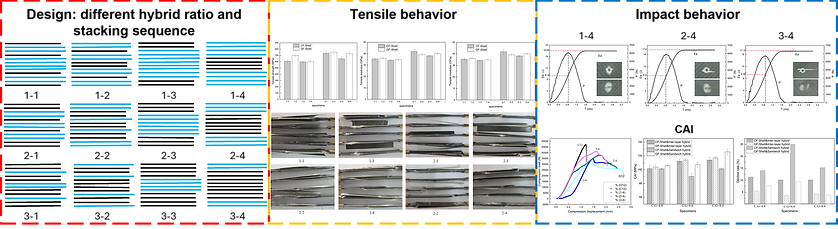

Optimized the carbon/glass fiber hybrid ratio and lay-up configuration through mechanical testing (quasi-static tension and compression, drop-weight impact, and CAI), ultrasonic scanning, and metallographic observation.

-

Manufactured the helmet via VARTM process; validated its performance through drop weight impact, flame retardancy, and electrical conductivity tests, achieving 53% weight reduction, high resistance to deformation and impact compared to traditional helmets.

-

Devised a custom pre-forming device with a multi-porous upper mold and a negative pressure fan beneath, increasing the production rate by three times.

bottom of page